Digital transformation in manufacturing is not what you think it is

10 minutes, 36 seconds read

“The year 2020 is just 18 months away. Where are you on the path to achieving your Digital Transformation goal?”

The Executive sitting across from me in the meeting room had already developed enough trust in me after several conversations. So he just replied with the truth: “Quite frankly, nobody knows where to start.”

A year and a half might seem like a long time for most people. However, for a company like this, one of the largest industrial machinery manufacturers, it’s the blink of an eye.

We were in a meeting room at the regional headquarters of their company in Paris, France. He was showing me the slides with his organization’s 2020 Objectives.

The PowerPoint presentation was prepared in 2013 by a management consulting firm when 2020 sounded far enough in the future. It looked very similar to many other “2020 Transformational Goals” slides that I’ve seen in the last years in similar conversations.

I’m almost sure the Big Four Consulting firms all use the same presentation template and content. It typically has anywhere between ten to 20 (!) “Key Objectives” that, after a deep (expensive) analysis, the consultants concluded the company needs to tackle. It usually contains vague goals like Deliver World-Class Quality, Become a Great Place to Work, and Digital Transformation.

Some of the more precise recommendations come in buzzword-rich prose: “become future-proof by leveraging exponential technologies (automation, AI/ML, IoT, Blockchain, additive manufacturing) to disrupt ourselves before new-entrants disrupt us”.

For the most part, the companies do a good job moving the needle when it comes to productivity and other hard metrics. But they almost always stumble on Digital Transformation, whether by inaction or other common mistakes. I see this over and over again, across geographies and verticals, but with higher frequency in manufacturing and other industrial environments.

Let’s go over some of the common mistakes.

Common mistake 1: Excessive Automation

While it is true that robots are getting exponentially better, with the ability to even work side by side with humans, a typical issue is the automation of waste. Peter Drucker used to say:

“There is nothing quite so useless, as doing with great efficiency, something that should not be done at all.

By merely replacing people with robots, we risk perpetuating processes that are unnecessary, inefficient or overengineered. Automation makes it much harder to make any changes to the process later on, and incremental improvements (which a person can easily adopt) are highly discouraged.

Also, the Return on Investment of the automation is not always realized. This case is typical: a robot might help eliminate the need for ten working hours in a given process. However, to program and maintain the robot, you then need to hire an engineer that is ten times more expensive than the reduced labor.

Finally, a common consequence that those of us in Lean Manufacturing see frequently: the high cost of the robot will encourage executives to “maximize the utilization of the asset” to amortize the investment. This typically results in overproduction of unnecessary parts, which leads to higher work-in-progress inventories, handling costs, and other hidden expenses.

Common mistake 2: Superficial Digitalization

It looks like this: all managers are instructed to take all their paper documents, and turn them into digital files. A slightly more advanced step is to identify all forms that are filled with pen and paper and turn them into interactive forms in a computer (tablets add an extra wow factor).

This approach is not wrong in itself. But it gives the false illusion of becoming digital without actually improving workflows, solving problems, increasing collaboration, or thinking about how the massive amount of data that is now digital can be used to gain insights and make better decisions.

Common mistake 3: Data Proliferation

Let’s say your company decides to get into the IIoT (Industrial Internet of Things) wave. You invest a considerable amount of money installing sensors on every single machine (“assets” in IIoT-lingo) and a few extra ones to measure environmental temperature, lighting levels, and such.

They do all this with the belief that “data is the new oil,” and that real-time insights on production conditions will naturally translate into benefits for the company.

However, what really happens is the following: a ton of uncategorized data is generated. Then, it sits idle for a while in a database. Finally, when the IT team tells Production that they are using too much space on the local servers, it is archived elsewhere (this typically happens every three months). The hope remains that this data will be of use in the future, perhaps during a post-mortem analysis.

The worst mistake: inaction.

When it comes to Digital Transformation in manufacturing environments, many companies decide to do nothing. They wrongly believe their people are not ready to handle digital technologies. Many executives in charge of the initiative are far from the frontline of work: the manufacturing shop floor, the warehouses, and the field.

Therefore, they cling to an antiquated notion that the industrial frontline is still about low-skilled repetitive labor performed by undereducated people: no place for digital technology. The irrefutable evidence: none of their desk-less frontline employees have a corporate email address or access to the company’s intranet.

This sad perception is far from reality. The industrial frontline has a fresh face. The people there are avid users of technology, especially the digital-native millennials that are flooding the workforce. All of them have an internet-connected supercomputer in their pocket. Yes, even in developing countries.

They go every day to their technology-poor workplace to use decades-old methods to perform their work. They are hungry for change, full of ideas, and they are eager to be given a chance to make a difference.

Your industrial frontline is digital-ready. It’s time for your company to step up.

A framework to start Digital Transformation in Manufacturing

Keep in mind: the purpose of Digital Transformation is not to adopt technology for the sake of technology. It is to generate enduring value by improving how you serve all your stakeholders. A big part of that is enhancing your operational system and the people who work in it.

1. Don’t generate new data if you are not willing to use the knowledge you already have

Data is certainly valuable. However, there are hierarchies of value: data < information < knowledge. Only knowledge can lead to insights and action. And where is the most relevant knowledge? In your people at the frontline: those who are closest to your processes, your products and your customers.

2. Use the technology at your hands (literally)

It is easy to fall in love with what is new. However, before introducing new technologies with unknown benefits and learning curves, start with what your people already know how to use: smartphones and tablets. Connected mobile devices can give your people the knowledge and tools to improve their work and collaborate with each other, even across countries.

3. Develop a network of frontline employees: the more, the merrier

According to Metcalfe’s law, the value of a network is exponentially proportional to the number of its nodes (in this case, your people). It would be foolish to limit the participation to only a limited population in your organization. Include everyone everywhere.

4. Shorten the action loops

Most companies make the mistake of collecting large volumes of data for several months, then doing analysis, and finally launching a few projects based on the insights.

A better way is to empower your people at the frontline (those closest to where the value is being created and delivered) to take immediate action on the smallest improvement ideas as soon as they detect a problem or opportunity.

While some people shun incrementalism, the truth is this: if you don’t foster a culture where people take action on small improvements, it is absurd to believe you will be able to execute larger and riskier transformations.

5. Continuously and automatically improve the system

With the use of machine learning, it is now possible to make sense of all the data and knowledge flow and determine what most impacts your business results. What are the best incentives? What are the attributes of the most creative teams? What is the best way of solving a particular type of problem? How can we send the best practices exactly where and when they are needed?

People are an essential part of your Digital transformation

Technology should be used to augment your workers, rather than to replace them.

By tapping into the collective intelligence of your frontline workers, you will generate tangible value for your organization. Most importantly, you will honor the inherent value of your people by enabling their creative capacity.

2020 is around the corner, have you started your Digital Transformation? The frontline is waiting.

Top Digital Transformation Trends in Manufacturing

We’ve touched on three of the biggest digital transformation trends in the manufacturing sector – 3D printing, advanced robotics, and the industrial internet of things (IIOT). Let’s dive a little deeper into the key elements and how they are driving the fourth industrial revolution.

3D Printing

The concept of 3D printing is no longer new in the tech space but manufacturing companies have been slower to adapt. It offers a multitude of benefits, including the ability to make small production runs without the usual high set-up costs. But it also offers a lean alternative to the waste that’s often created by automation. 3D printing allows something that was once a mass manufactured product to be created on-demand. This reduces over-supply and unnecessary stock storage while keeping lead times short for customers.

Manufacturing operations that leverage 3D printing are also well-placed to adapt with shortening product life-cycles. Processor chips and super-fast cables have become increasingly smaller and speedier, meaning products have an ever-decreasing shelf-life. As customer experiences and expectations shift, they are purchasing replacements more frequently. Manufacturing executives need to take actions now that will ensure their operations can keep up with accelerating demand. Incorporating 3D printing in their workflow is one way they can achieve this.

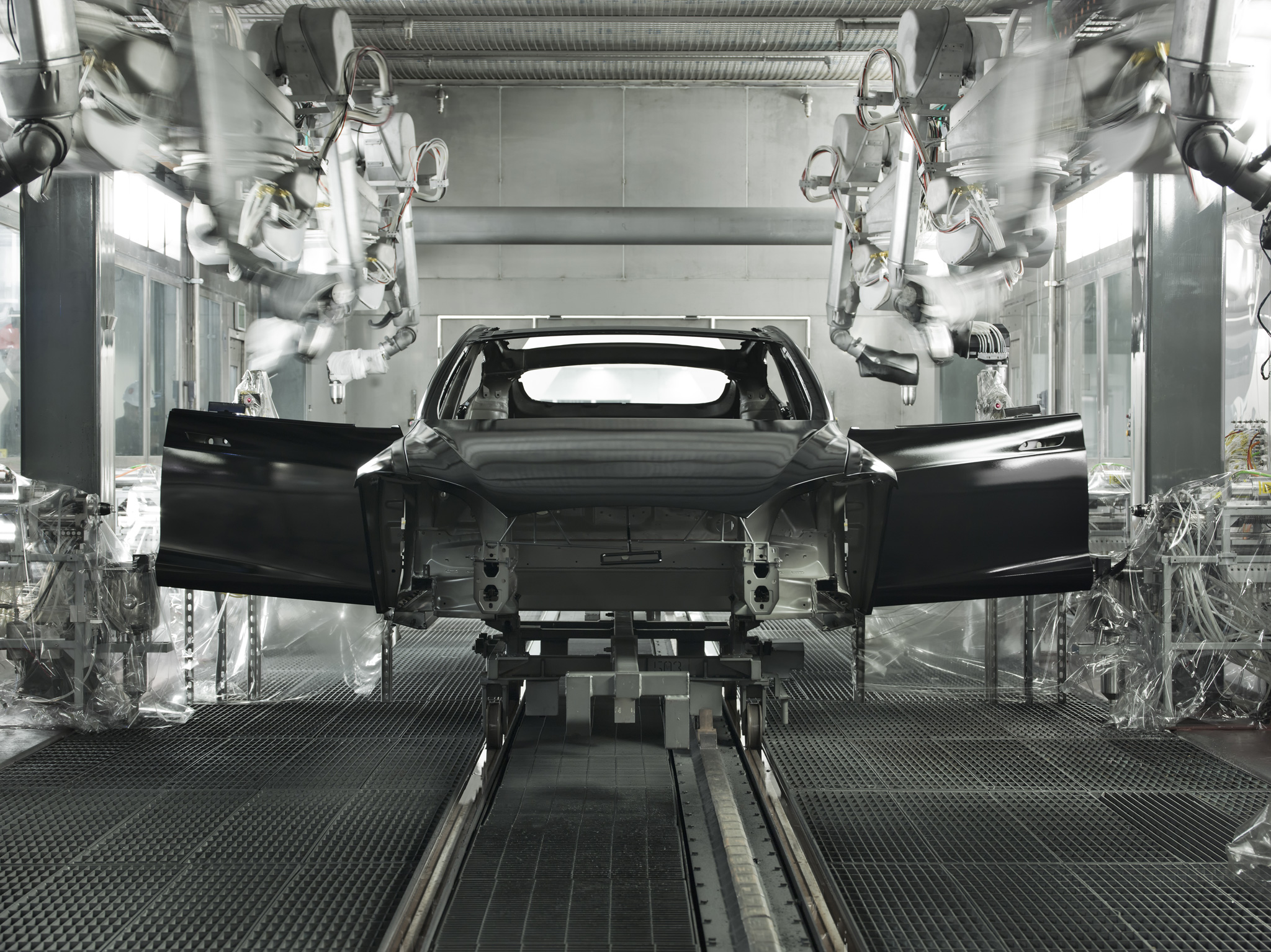

Advanced Robotics

This feels like it’s been a manufacturing trend for years but evolving technology means we never quite catch up. Advanced robotics is helping to improve product quality, productivity, and safety for workers. Most manufacturing industries have adopted some kind of robotics into their operations but new advancements mean there’s always room to improve and adapt. The most effective digital transformation happens when companies embrace change and adopt a continuous improvement mentality. This ensures that they don’t get left behind as technologies continue to evolve.

Advanced collaborative robots are also enabling manufacturers to meet the increasing quality expectations of customers. The proliferation of online reviews and social media means that consumers have access to more data about your products than ever before. So, if they aren’t quite up to scratch and it results in negative reviews, the decrease in sales is multiplied. Instead of someone just telling their friends about a poor experience, their review can now be read by thousands of potential customers. Savvy manufacturers are employing advanced robotics and artificial intelligence to maximize quality control and identify potential defects before they enter the supply chain. The drive toward digital transformation is also enabling advanced analytics to be produced that highlight opportunities for improvement and leaner processes.

Industrial Internet of Things (IIoT)

The internet of things (IoT) has now entered our daily lives as cars, homes, and appliances have become connected to the web. It has also impacted the digital transformation of manufacturing as more IoT platforms become integrated. The installation of sensors has resulted in connected manufacturing where machines can communicate and react to each other. Although this can result in unnecessary data collection, it can also drive lean processes when approached correctly. Sensors can immediately tell you when vital temperatures have been reached, avoiding wasteful overheating. They can switch lighting off when it’s not required, saving vital hours of electricity and producing a meaningful cost-saving. The industrial IoT may not be a silver bullet but with a strategic approach, it can have impressive bottom-line results.

Like this content? Sign up for our Newsletter

THE FRONTLINE DOJO

More Articles

How to develop the next billion Knowledge Workers

3 minutes, 51 seconds read

Digital transformation in manufacturing is not what you think it is

10 minutes, 36 seconds read

The human side of change management: lessons learned from Toyota, Airbus, and Silicon Valley

1 minute, 28 seconds read

The true meaning of Genchi Genbutsu

3 minutes, 5 seconds read