6 Continuous Improvement Tools & Techniques

12 minutes, 11 seconds read

Continuous improvement tools are a powerful resource in the lean manufacturing journey. Leveraging the right one can lead to improved productivity, reduced errors, and greater profitability overall. There are many different continuous improvement models that can help a business reach their lean ideals. But how do you know which one is most suited to your organization or specific challenges? In this article, we look at a range of options that can aid process management, streamline quality control, and improve efficiency.

Continuous Improvement Tools and Methodologies

Over the years, numerous tools, techniques, and systems have been designed to aid improvement. They are intended to give businesses a framework so that they don’t have to create their own from scratch. This allows them to learn from the best practices of others and leverage what’s been proven to work. However, knowing the difference between processes and terminology can be confusing. With so many options to choose from, how do you know which one is right for your specific business needs? Here’s an overview of the six most popular and effective continuous improvement tools available.

1. PDCA

The PDCA cycle (short for plan, do, check, act) provides you with a systematic approach to testing different ideas and hypotheses. It can help you to implement continuous improvement throughout your organization using a structured framework. If you want to improve business processes, efficiency, or productivity, then the PDCA cycle can help.

The framework gives front line teams a four-step guide for executing incremental improvement practices. It enables them to avoid making the same mistakes repeatedly and is commonly used in lean manufacturing. PDCA stands for:

- Plan – define your strategic goals and how you’ll achieve them.

- Do – implement the plan and make any changes required to ensure it works.

- Check – evaluate the results and identify opportunities for improvement.

- Act – make adjustments based on what’s found in the previous step.

Some companies follow a slightly modified PDSA cycle, where the S stands for ‘study’ instead of check. It’s very similar to PDCA but involves passively observing instead of proactively checking. The simple format means that PDCA is one of the most easily adopted continuous improvement tools. Everyone in a company can understand and follow the four steps as they’re relatable in a wide variety of job roles, from human resources to R&D. It facilitates continuous process improvement and empowers employees to test ideas on a small scale. Over time, this creates a culture of creativity and innovation which is difficult for your competitors to replicate.

One of the key benefits of PDCA is that it’s easy to understand and remember. The acronym can quickly become a mantra that is repeated and utilized by everyone in the business. Some companies display the process on posters around their buildings while others print it on to mouse mats and coffee mugs. This gives employees a visual reminder and encourages them to adopt it as a consistent part of their work routine. The 4-step process doesn’t require weeks of training to understand either – it can be summarised clearly in a matter of minutes. Managers can then follow-up with staff as they implement it and help them to learn on the go. This approach to coaching means there isn’t a large barrier to implementation in terms of training. Companies can hit the ground running and then tweak it as they go along.

2. Gemba Walks

When it comes to continuous improvement tools, Gemba walks can be particularly powerful. They enable you to tap into the most valuable resource a company has: its people. The most innovative improvement ideas often come from the employees who are working on the front line and problem-solving on a daily basis. They have an in-depth understanding of their particular area of the manufacturing process and are able to provide potential solutions.

Smart managers understand that the best way to capture these valuable insights is to get out of their offices and into the ‘Gemba’. This is the place where things actually happen, such as manufacturing or product development. Gemba walks involve interacting with staff on an informal basis at the location where they do their work (as opposed to a meeting room). It enables observation of real-life situations or the actual production process so that leaders have a better idea of things that are happening. This casual yet accurate form of data collection can be a powerful tool for companies that like simple improvement tools and techniques.

Regular Gemba walks also develop better employee relationships and a greater focus on continuous improvement. They provide a framework for regular interaction and create a habit of consistent feedback collection. However, it’s important not to use them as an opportunity to reprimand staff as this will make them less likely to open up and share their thoughts. This approach is best used to observe and collect data which can be used to inform future decision making.

As you might have noticed, this is a tool that’s specifically designed to gather feedback. It’s a data collection process that allows managers to tap into the vast knowledge of their team members. However, it’s not an end-to-end solution for improving business processes since it doesn’t facilitate the implementation or measurement. It is simply intended as a way to gather ideas and suggestions that can then be followed-up later. So, if you are going to try this approach, it’s really important that you have a mechanism in place for acting upon what you learn. You can use it in combination with other tools on this list or a follow-up process of your own.

3. 5 Why’s

The 5 why’s is one of the best continuous improvement tools for root cause analysis. It can help you to identify the source of a problem and see beyond the superficial issue. By asking ‘why’ several times in a row, you can dive deeper into the heart of a problem. This enables you to them come up with potential solutions that accurately address it instead of just treating the symptoms. It also helps teams to move past apportioning blame or finger pointing to find the real issue.

Using the 5 why’s technique can also help you to determine the relationships between cause and effect (ideal for creating a fishbone diagram). It’s a simple tool that anyone can utilize without the need for statistical analysis like data regression or hypothesis testing. Businesses may find that they need to ask ‘why’ a few more times or a few less to get to the root of an issue. But this approach is a full proof way of getting to the heart of anything that isn’t working.

However, as with the Gemba Walk approach, this is not an end-to-end solution. It’s a powerful method for getting to the heart of an issue and identifying improvement opportunities. But it doesn’t facilitate the implementation of any ideas or provide a structure for coming up with solutions. It’s intended to help businesses get to the real issue instead of being distracted by superficial answers. This makes it a very useful tool to have in your arsenal but one that needs to be combined with others in order to enact meaningful change.

4. Toyota kata Coaching from Managers

The Toyota Kata concept was observed by Mike Rother as part of his research into the car company. Renowned for its Kaizen culture of continuous improvement, he noticed behavior patterns or ‘katas’ that were contributing to it. One of these katas related to the coaching of employees so that they learn, improve and focus their efforts in the right direction.

If you feel that your team is unmotivated or no longer developing, then Toyota Kata coaching can help them to improve effort. It sets regular challenges for them to achieve so that they’re always striving for continuous improvement. They are encouraged to develop daily improvement routines or habits that eventually become second nature. This approach provides a structure for continuous learning and development. This helps to reengage employees who feel stuck or those that have hit a plateau in their professional growth. Over time, this contributes to quality improvement and boosts productivity, so that your employees, customers, and bottom line all benefit.

There are a series of questions that managers can use to facilitate Kata Coaching with their staff members. They are designed to prompt reflection and self-development on the part of the employee. These questions are:

- What was your last step?

- What did you expect to happen?

- What actually happened?

- What did you learn?

Using these questions provides a framework for coaching discussions. They encourage employees to be proactive and think for themselves. They put the onus on staff members to identify issues and development areas so that it’s not just a one-way discussion. This aids engagement and helps to ensure that meaningful learning takes place.

5. 3M’s – Muri, Mura, and Muda

The 3M’s were identified as part of the Toyota lean production system. They refer to three different categories of deviation that cause problems for companies. These issues can manifest themselves in manufacturing, research and development, marketing, or any number of other departments. The 3M’s refer to Japanese words that are usually translated as:

- Muri – overburden caused by lack of resources, poor planning, or too much waste removal.

- Mura – unevenness or irregularities which tend to be the source of ‘muda’ waste issues.

- Muda – waste such as excessive transport, inventory, waiting, overproduction, or defects.

In pursuing a lean management approach to business, the 3M’s is one of the best continuous improvement tools for identifying problems that also eliminates waste. It can be used to highlight issues or opportunities for operations to become leaner. The system is helpful for total quality management and promoting the adoption of lean practices that create value for the customer.

It can be helpful to work through the 3M’s in turn. Looking for examples of Muri or overburden in your business will enable you to identify areas that need more resources or could benefit from better planning. Finding the sources of Mura or irregularities in your products will facilitate the next step of decreasing Muda or waste. It’s also important to consider other sources of waste too in order to streamline your lean operations to their full potential. This will allow you to focus on the elements that drive customer value and minimize the wasteful aspects that drain resources unnecessarily.

6. Continuous Improvement Software

There are now many digital continuous improvement tools that offer powerful business benefits. They tend to leverage the best aspects of other improvement tools and combine them into one easy-to-use solution. Online platforms enable companies to easily capture ideas and feedback from employees. Some have built-in guides that walk people through continuous improvement processes (such as the PDCA cycle), empowering them to take action.

Continuous improvement software also makes analysis and reporting a breeze. Instead of spending time creating complex spreadsheets or gathering key performance indicators from different departments, reports can be generated instantly. This enables you to see how your company is progressing towards its continuous improvement goals and how productivity, profitability, or quality are being impacted.

Digital solutions also free up the flow of information. Because everything is stored centrally, there are no bottlenecks to delay steps in the process. Employees are able to see the progress of their suggestions or share updates on tests that they are running. This is a powerful step to removing silos between different departments and creating a culture of collaboration. It also removes the burden of ownership from specific team members and makes employees more accountable for making changes happen. The improved visibility leads to greater buy-in and a flurry of additional improvement ideas that can benefit the company.

Your Digital Continuous Improvement Tool

Rever is all about sharing and reusing, doing and tracking. Continuous improvement becomes a hundred times easier with our innovative digital platform. Using Rever’s dashboard, you can monitor the performances of your teams, the summary of their impact, and easily identify the people making the biggest difference at your company.

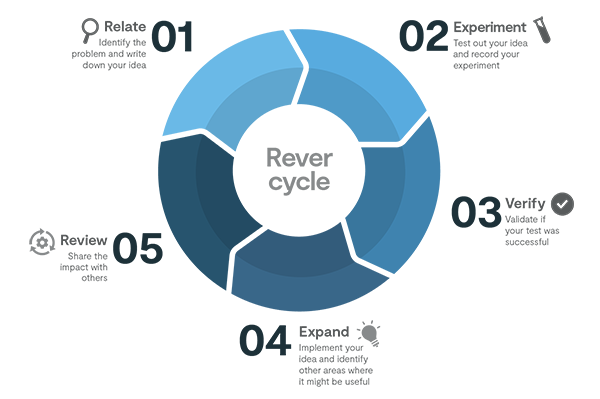

Rever Cycle is our version of the PDCA methodology and guides your teams on the exact steps to follow to execute their own ideas. It allows them to capture the entire process, from identifying a problem to experimenting and implementing a solution. They can use it to capture the before and after with pictures, notes and drawings, making their ideas a reality in no time. The time of your team is too valuable to be wasted in handmade drawings and complex explanations.

At Rever, we believe that anybody can be a knowledge worker and thrive. What makes us human is the capacity to grow our intellect and will, and to use them for good. We observe, especially at work, that most people are asked to stop thinking and do as they are told. We want to change that. We enable people to achieve their full creative potential.

Interested in learning more? Then get a demo today with one of our friendly lean management experts.

Like this content? Sign up for our Newsletter

THE FRONTLINE DOJO

More Articles

How to develop the next billion Knowledge Workers

3 minutes, 51 seconds read

Digital transformation in manufacturing is not what you think it is

10 minutes, 36 seconds read

The human side of change management: lessons learned from Toyota, Airbus, and Silicon Valley

1 minute, 28 seconds read

The true meaning of Genchi Genbutsu

3 minutes, 5 seconds read

3 thoughts on “6 Continuous Improvement Tools & Techniques”