REVER LIBRARY

Operational Routines

Ensure operational routines are executed in a timely and consistent manner. Findings are addressed at the source or assigned and follow-up tracked.

ACTIVATING THE UNTAPPED POTENTIAL OF THE FRONTLINE

Today's Challenges

Routines are not executed in a consistent manner and follow-up on findings is unpredictable.

- Performance improvements are detected but not given attention

- Critical routines are not executed in a timely & consistent manner

- Findings are not captured, assigned, and completed effectively

Rever Benefits

Ensure operational routines are executed in a timely and consistent manner. Findings are addressed at the source or assigned and follow-up tracked.

- Ensure operational routines and activities are executed consistently

- Assign routines to the frontline with specific actions to be taken

- Unified view of routines and their findings

- Standard process to ensure findings are being addressed, documented, and learnings shared

HOW REVER HELPS

Prepare & Publish a Routine

1

Define the routine including all specific parameters.

Publish the routine to the appropriate business units.

Key information

-Process

-Timing/Frequency

-Location

-Deliverable

Execute the Routine & Capture Findings

2

Routine executed.

Participants capture findings and assign them to the routine.

Key information

-Finding Description

-Location

-Picture

Follow up on Findings

3

Employees can follow a guided workflow to create a virtual team and drive the finding to resolution.

Standard documentation is created through the process.

Share & Report

4

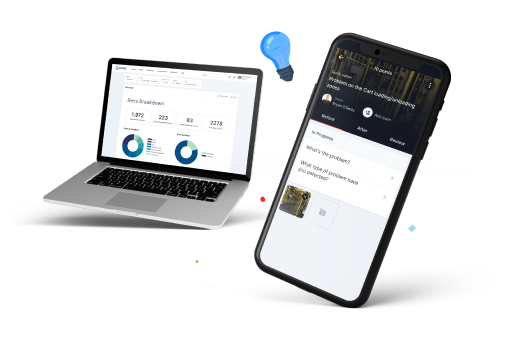

Track progress and report results of routines, as well as their associate findings.

Share learnings across the organization.

Recognize individuals for their work and impact.

IN ACTION

Industrial Manufacturing

Create a ‘Go and See’ Routine

Supervisors create the routines for different activities such as: Quality, maintenance, safety, BBS, 5S that needs to be addressed in operation.

Supervisors create the routines for different activities such as: Quality, maintenance, safety, BBS, 5S that needs to be addressed in operation.

Register, Prioritize & Communicate

Team members and supervisors complete the audit routines and register issues. Issues are addressed at the source or escalated.

Team members and supervisors complete the audit routines and register issues. Issues are addressed at the source or escalated.

Register findings and address issues

Supervisors track the progress on solutions and pending findings to be addressed.

Supervisors track the progress on solutions and pending findings to be addressed.

Automotive Manufacturing

Create Daily Performance Audit Routines

Ensure every shift maintains the proper equipment and operational standards and parameters.

Ensure every shift maintains the proper equipment and operational standards and parameters.

Register findings and address issues

Team complete the Audit Form and register any exceptions. Exceptions are addressed at the source or escalated.

Team complete the Audit Form and register any exceptions. Exceptions are addressed at the source or escalated.

Track & Share

Supervisors track the progress on solutions and pending findings to be addressed. Pending solutions and highlights need to be shared with the people involved.

Supervisors track the progress on solutions and pending findings to be addressed. Pending solutions and highlights need to be shared with the people involved.