WESTEC 2019 Recap: Supporting Rapid Innovation with Incremental Improvement

2 minutes, 22 seconds read

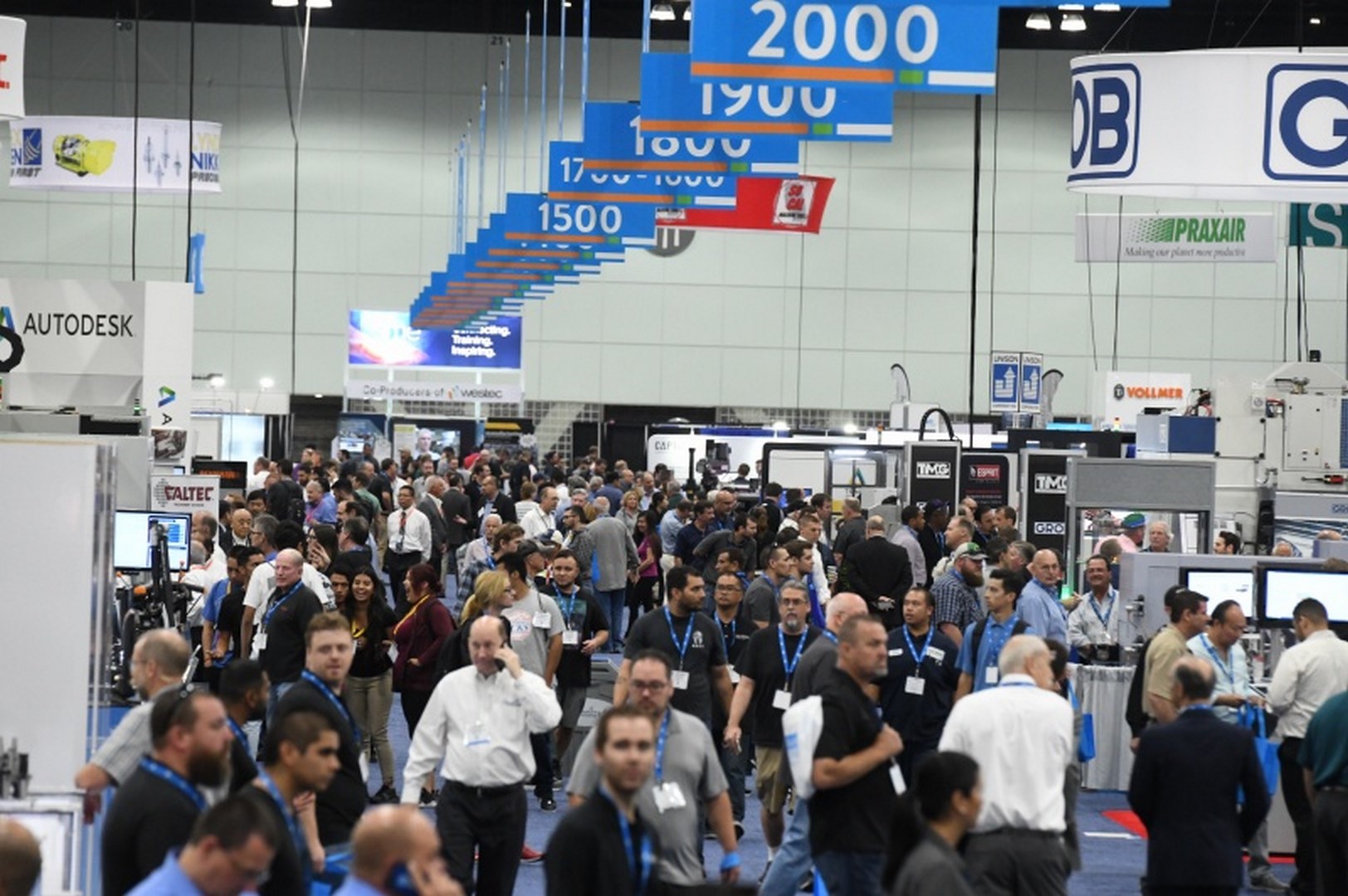

We often feel that the rate at which companies are introducing new technology innovations seems to be moving faster than ever, but last week WESTEC confirmed it. The biennial West Coast manufacturing trade show produced by SME and AMT brought its usual blend of tech displays and mind-opening education. But it was Tom Wujec, Chief Disrupter at Autodesk, during his keynote address on The Future of Making who noted that AI is the fastest-adopted developing technology to date.

Wujec pointed out that technologies such as 3D printing, artificial intelligence and virtual reality allow us to create things in ways we never imagined a few short years ago. However, designers at the leading edge of innovation use these technologies as partners to augment human intelligence and capabilities.

More accurate data

Wujec attributes much of this momentum to a new disruptive creation process Autodesk calls Rip-Mod-Fab. We “rip” the world to get ever-more accurate digital pictures. Then we “modify” these models with advanced simulation tools. Finally, we “fabricate” the net result in physical reality. It’s a totally new way to imagine, communicate, manufacture, and sell physical products, from cars to shoes, movies to skyscrapers. Think of it as a digital “read, understand, and write” approach to design.

When this approach touches an industry, Wujec said, that industry is never the same. In other words, it has untold repercussions for every sector, from manufacturing and transportation, to real estate and healthcare.

More regular improvement

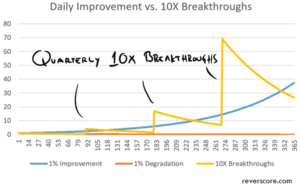

It’s tempting to think that only leaps in innovation have the power to drive improvement. But Rever founder and CEO Errette Dunn made the case at WESTEC for the bigger impact of incremental, 1% improvements.

Dunn noted that a culture of daily improvement encourages healthy habits like curiosity, problem-solving, persistence, enthusiasm, and engagement. Without these habits, companies can’t expect to cultivate breakthrough innovations. Continuous improvement, in fact, paves the way for radical innovation to flourish.

Moreover, Dunn has found that a breakthrough improvement sounds promising, but pales compared to the results of compounded daily gains.

More frontline involvement

Exponential results aren’t a hypothetical possibility. Dunn shared examples of how companies are boosting their efficiency by capturing incremental improvements from frontline workers.

For Dunn, the biggest improvements come from tapping into the collective innovation of frontline workers. By harnessing tech tools, companies can encourage deskless teams to “modify” and “fabricate” process experiences through improvement experimentation and implementation.

By drawing upon ideas from a larger pool of innovators — the frontline operators most knowledgeable about the end product — companies can drive massive improvements in bottom line efficiencies and top-line business growth. As more manufacturers are finding in the shift to Industry 5.0, technology works best when supported by human intelligence.

Like this content? Sign up for our Newsletter

[hubspot type=form portal=561211 id=fda6d445-739e-4072-8dae-68b94971a266]THE FRONTLINE DOJO

More Articles

How to develop the next billion Knowledge Workers

3 minutes, 51 seconds read

Digital transformation in manufacturing is not what you think it is

10 minutes, 36 seconds read

The human side of change management: lessons learned from Toyota, Airbus, and Silicon Valley

1 minute, 28 seconds read

The true meaning of Genchi Genbutsu

3 minutes, 5 seconds read